Whenever you buy a house or rent an apartment, everyone has loads of home improvement ideas. At some point you realize there are only so many changes that can be made, but if you could build your own house? Man, the great ideas you?d build into the design.

We felt the same way about our warehouses for bottled wine. As we’ve grown over 30 years, we found ourselves spread out in different warehouses across Northern California; it was time for us to start over.?We wanted our new warehouse to show the same concern for sustainability that we have in the vineyards and winery.

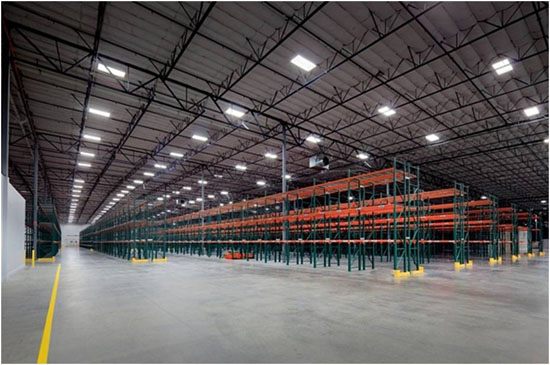

The outcome was an award winning building called the Napa County Distribution Center (NCDC). ?The NCDC is the only refrigerated warehouse to receive Gold Certification by the U.S. Green Building Council?s Leadership in Energy and Environmental Design?(LEED) program.?LEED is an internationally recognized green building certification system to improve performance in environmental quality and stewardship of natural resources.

Here are some of the elements we incorporated in our design; you may be surprised how many of them can be applied into a home design too:

Energy Efficiency

Saving energy saves money; we invested over $250,000 in energy efficiency upgrades. Keeping wine cool is critical to maintaining quality, and we focused on reducing air conditioning needs. The building shell is protected by heavily insulated interior walls and a thermally efficient cool roof system.? Dual-pane glass with a special coating and operable shades on the windows minimizes heat gain during the summer and heat loss during the winter.

High efficiency lighting and many other conservation measures enable the building to use 38% less energy than standard warehouses, resulting in an annual savings of almost 2,000,000 kilowatt hours ? ?enough to power 308 homes. ?We also purchased renewable energy?for 100% of the energy use.

Ecosystem Management

The NCDC ?is the first environmentally sensitive commercial development in ?rural ?Napa County.? The site was historically used for cattle grazing and the planning team gave careful attention to maintaining the natural environment.

Excluding the building footprint, over 55% of the site has been maintained as dedicated open space – a 1,700% increase over zoning requirements. Additionally, wetlands were expanded to 1 ? acres and a series of bioswales were added to capture rainwater runoff.

?

Rail Shipping

Rail shipments are more energy efficient than truck shipments so we built a 1,900 foot rail spur to connect to the local railroad. Rail shipments are now up by 20% and we now ship 60% of our wine on trains. We?re?saving 410,000 gallons of fuel per year that would have emitted 4,230 tons of CO2, that?s equivalent to taking 830 cars off the road.

Building Materials

The design team carefully chose building materials based on sustainable characteristics. These choices are complicated, take time, and can cost a little more, but they result in a healthier work environment. All sealants, adhesives, paints, coatings and carpet systems are low-VOC.? Regional sourcing accounted for 42% of all building materials which decreased the environmental footprint of transportation.

Additionally, recycled content accounted for 29% of the total combined building materials including concrete, aggregate, acoustic ceiling tiles and glass countertops.? 84% of all construction waste was recycled and diverted from landfills.

Water Conservation

Water is a more precious ?commodity than many of us realize, especially when we look at how much energy and cost goes into wasting water. Native and drought-tolerant landscaping was combined with drip-irrigation resulting in a 56% water use reduction.? Inside the building, water efficient plumbing fixtures save 44% over typical consumption.

A chemical-free water treatment technology was used for the heating and air conditioning equipment.? Had a typical chemical treatment system been used instead, it would release 2,600 pounds of chlorine gas into the environment annually.

At the end of the day, we learned a lot on this project and had a lot of fun building one of the ?greenest? buildings in the country ? and it looks pretty sweet too.